What is UV Bonding ? Intro to UV Glass Bonding

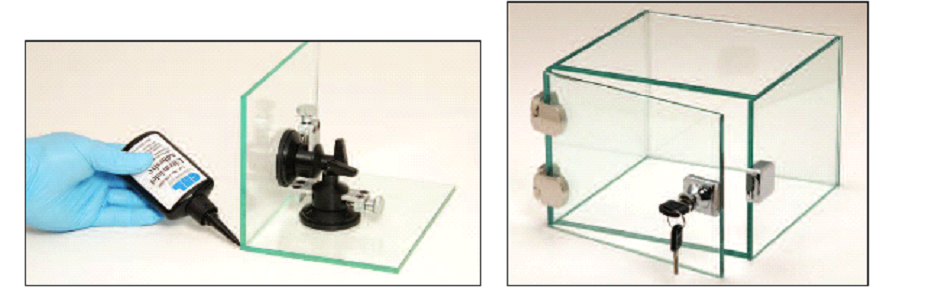

UV bonding is a process where two pieces of glass are glued together with a UV curing adhesive, which is cured either by a UV activator or UV light. This technique is also used to adhere aluminum or stainless steel hinges, locks and knobs to glass. The most popular use for UV bonding is the construction of glass showcases and furniture.

The glued joints display no visible sign of the glue and offer a clean, professional and refined look. They are also stronger and more durable.

Glass bonding systems

A glass bonding system consists of all the hardware necessary to craft everything from glass furniture to glass artwork.

- Innovative fixation devices to hold the glass securely in place

- A vast selection of UV lamps at different intensities

- High quality UV adhesives (high, medium and low viscosity formulas)

- Glass furniture hardware that remove the need for cut-outs, notches or drilling holes in glass

C.R. Laurence glass bonding system from C.R. Laurence usually includes starter kit or professional kit, along with cleaners and accessories to get started with your hobby or work project.

Tips on using adhesives

When using UV curing adhesives for glass-bonding, you will need to consider the following:

- The suitability of the adhesive to the glass being used. For instance, laminated or colored glass - which have high UV absorption – won't work with common UV adhesives and need special adhesives that react with radiation and cure by daylight.

- Bonding surfaces must be clean, dry and grease-free. Conventional surface cleaners cannot be used in most cases, and only those that don't contain surfactants or other contaminants are suitable.

- Selection of the right adhesive is an important step. This will depend on factors such as the bonding materials, the application(s) of the product, and the stress load.

- The adhesive must be applied within five minutes of the parts being heated. It is recommended that the parts are positioned horizontally during application. The adhesive should be spread evenly and precisely, taking care to move air bubbles to the side.

- The bonded surfaces must be stable and kept in a fixed position; fixation devices will prove useful here.

- When curing UV adhesive, it is best to use UV safety glasses as an additional precautionary measure.

- A bond test of the surfaces to stress will confirm their strength and ability to resist force and sudden movement.

A thorough understanding of everything the UV glass bonding process entails is advised before attempting the desired construction.