RECENTLY VIEWED

Skip to main content

The CRL B7S Series Heavy-Duty Square Base Shoe is used as the base channel for glass railing systems. It can be clad in six choices of architectural finishes. The most critical component in a railing system is the proper attachment of the Base Shoe to the substrate. CRL has engineered and tested a variety of attachment methods, and has developed an acceptable combination of drilling patterns and fasteners. A printed brochure with instructions, installation hints, cleaning, and refinishing techniques is available.

GLASS SPECIFICATONS:

3/4" (19 mm) Thick Glass when using TAPER-LOC Dry Glaze System or Wet Glaze System.

Product Warning:

All heavy Base Shoes have a stock length tolerance of plus or minus 3/4" (19 mm). CRL does not recommend direct powder coating of this base shoe extrusion. Powder coated cladding applied over the base shoe is the recommended method.

All pre-drilled CRL Base Shoes have a +1/8 (3 mm)/-1/16 (1.5 mm) tolerance between each hole drilled in the base. Before drilling installation holes in the concrete or steel substrate it is recommended that the installer place the base shoe into the planned final position, then mark the position of the holes to be drilled into the substrate.

DK Hardware Professional Tax Exempt? Net 30? - DK Net Terms

Roll over image to zoom in

Product Features

Product Overview

Related Videos

Reviews

Questions & Answers

CRL B7S10F B7S Series Mill Aluminum 120" Heavy-Duty Square Base Shoe Fascia Mount Drilled for 3/4" Glass

Item #: B7S10F by CR Laurence

See reviewsSee reviews

30 Days Easy Return. We are the largest supplier of the most adaptable, personalized hardware in the industry. We work hard to ensure you're satisfied with our products.

Features

- For 3/4" (19 mm) Monolithic Tempered Glass

- Typically Used as the Base Channel for Glass Railing Systems in Arenas

- Drilled and Counter Bored 12" (305 mm) Center-to-Center, or We Will Custom Drill to Your Specifications

- Custom Cutting and Mitering Service

- Test Reports Available

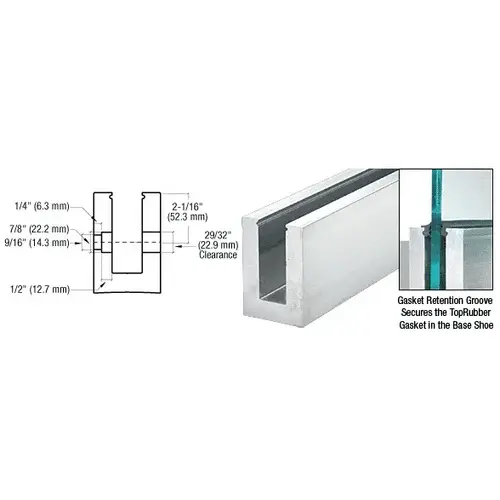

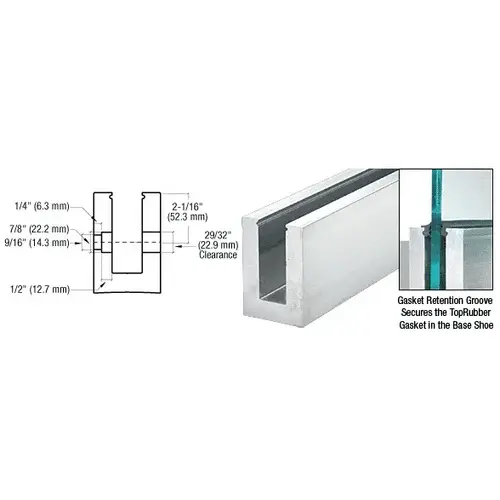

Counter Bore X Depth

7/8" (22 mm) x 1/2" (12.7 mm)

Hole Size

9/16" (14.3 mm)

Stock Length

120" (3.05 m)

Holes Drilled C.T.C.

12" (305 mm)

Finish

Mill

Material

Aluminum

Length

120

Glazing Thickness

3/4

Glazing Type

Monolithic

Drilling Center to Center

12

Finish/Color

Mill

Product Overview

The CRL B7S Series Heavy-Duty Square Base Shoe is used as the base channel for glass railing systems. It can be clad in six choices of architectural finishes. The most critical component in a railing system is the proper attachment of the Base Shoe to the substrate. CRL has engineered and tested a variety of attachment methods, and has developed an acceptable combination of drilling patterns and fasteners. A printed brochure with instructions, installation hints, cleaning, and refinishing techniques is available.

GLASS SPECIFICATONS:

3/4" (19 mm) Thick Glass when using TAPER-LOC Dry Glaze System or Wet Glaze System.

Product Warning:

All heavy Base Shoes have a stock length tolerance of plus or minus 3/4" (19 mm). CRL does not recommend direct powder coating of this base shoe extrusion. Powder coated cladding applied over the base shoe is the recommended method.

All pre-drilled CRL Base Shoes have a +1/8 (3 mm)/-1/16 (1.5 mm) tolerance between each hole drilled in the base. Before drilling installation holes in the concrete or steel substrate it is recommended that the installer place the base shoe into the planned final position, then mark the position of the holes to be drilled into the substrate.

Most shipping weights are approximate and have not been verified. If the exact weight is needed in order to determine shipping costs, and shipping costs are required in order for you to complete your order, please request this prior to submitting your order by contacting CRL Customer Service. Product images shown are of the actual product or a close representation. Colors can vary depending on your computer's video card and on how your monitor's color is adjusted.