Everything You Need to Know About Bulletproof Panels [ How Bulletproof Panels Work, Costs, Installation Tips & More]

![Everything You Need to Know About Bulletproof Panels [ How Bulletproof Panels Work, Costs, Installation Tips & More]](/blog/content/images/size/w2000/2025/08/1--6-.jpg)

Security concerns have grown sharply across schools, healthcare facilities, commercial spaces, and even private residences in recent years. Incidents involving armed intrusions have pushed administrators, architects, and homeowners to look for effective ways to protect occupants without turning buildings into unwelcoming spaces. Bullet-resistant panels have emerged as one of the most reliable solutions, offering discreet protection while blending with interior and exterior designs.

In schools & colleges, these panels are installed to create safe zones where students and staff can shelter in place during emergencies, buying valuable time until law enforcement arrives. Bullet-proof panels in healthcare facilities, on the other hand, reduce the risk of injury during violent incidents.

Homeowners are also turning to these panels to safeguard panic rooms, home offices, and key structural points. For high-profile individuals or those living in high-risk areas, bullet-resistant construction provides an added layer of defense against break-ins or targeted attacks. In most cases, the panels are installed behind drywall or decorative finishes, ensuring that the aesthetic of the home remains intact.

In this blog, we dive into the world of bullet-proof panels and understand what they are, how they work, and which one is right for your building. Additionally, we offer a range of Security Hardware, including products that complement ballistic protection systems, ensuring both safety and design integrity.

What Are Bulletproof Panels?

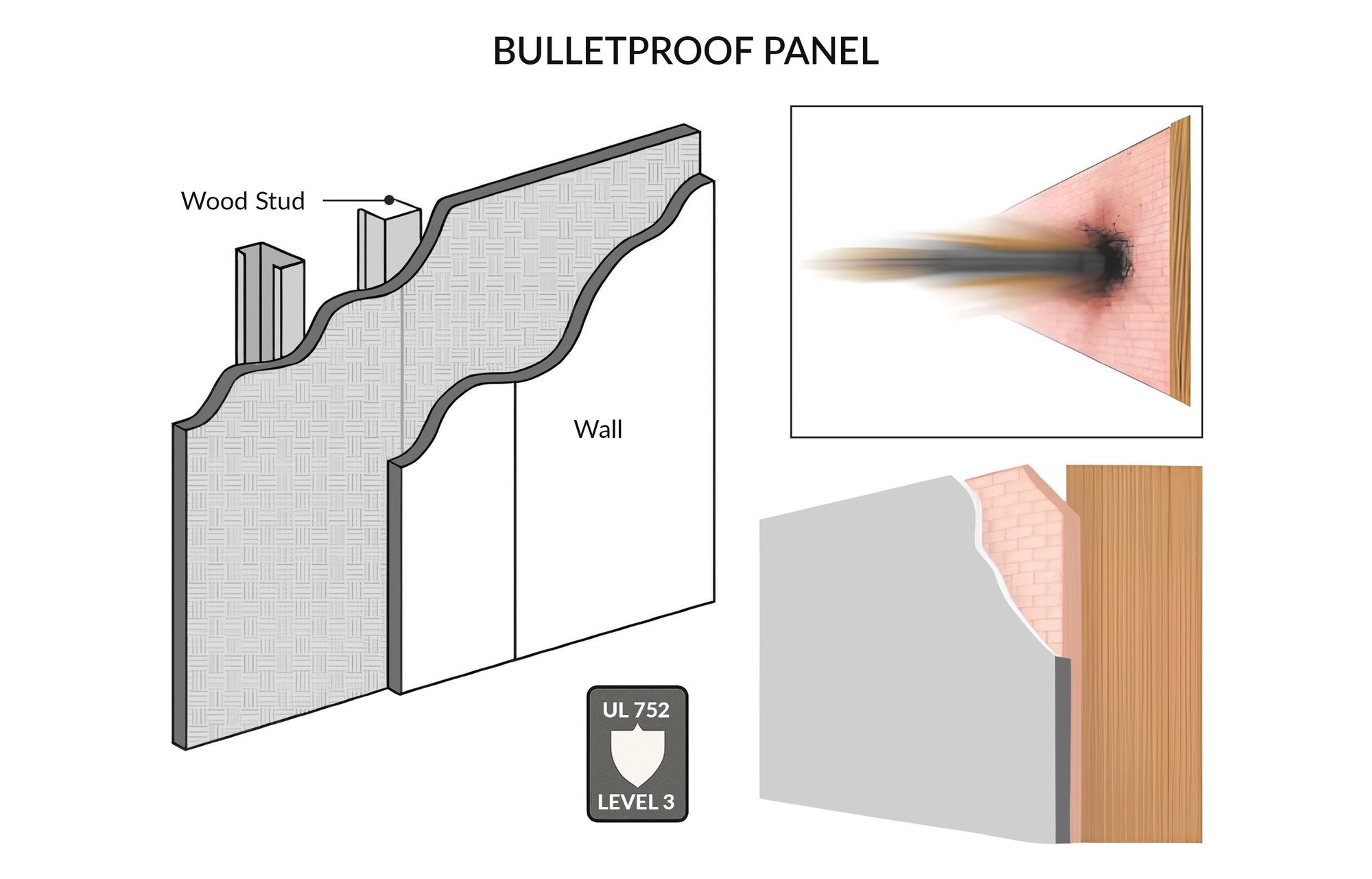

Bulletproof panels, also referred to as bulletproof or ballistic panels, are engineered materials designed to stop or slow down projectiles, reducing the risk of injury or damage. Unlike traditional construction materials, they are manufactured to meet specific ballistic protection standards, making them suitable for high-risk environments.

These panels are commonly made from materials like layered fiberglass, Kevlar, or ballistic steel, each offering different levels of protection, weight, and installation flexibility. They are tested to meet standards such as UL 752, ensuring reliable performance under real-world threat conditions.

Key Features:

- Discreet Protection: Can be installed behind drywall, millwork, or other surface finishes.

- Customizable Sizing: Panels can be cut to fit specific dimensions or architectural layouts.

- Versatile Applications: Suitable for walls, doors, counters, and partitions.

- Multi-Level Resistance: Available in ratings to withstand different firearm calibers.

Bulletproof panels are not limited to security-intensive facilities; they are increasingly being integrated into offices, retail spaces, and residential properties. Their ability to combine safety with aesthetic flexibility makes them a preferred choice for architects and security planners.

How Bullet-Proof Panels Work? (Controlled Delamination)

Bullet-proof panels protect by dispersing the force of a projectile across multiple layers of strong, flexible material. The most common technology behind this is controlled delamination - a process where the layers within the panel separate in a controlled way upon impact, slowing and trapping the bullet.

In bulletproof fiberglass panels, woven fiberglass sheets are bonded with resin and compressed under high pressure. When struck by a bullet, the fibers delaminate and stretch, absorbing kinetic energy and preventing penetration. This design minimizes the risk of ricochets or fragmentation, making it safer for occupants.

Key Steps in the Protection Process:

- Impact Absorption: The first layers take the initial energy from the projectile.

- Energy Dissipation: Multiple layers spread the force over a wider area.

- Projectile Capture: The bullet becomes trapped within the fiber matrix.

- No Spall Risk: Prevents dangerous fragments from reaching the protected side.

This method ensures a balance between high security and manageable weight, making panels suitable for doors, walls, counters, and security enclosures.

UL 752 and Ballistic Protection Standards

The UL 752 standard is the primary benchmark for rating bulletproof materials in the US, defining eight protection levels based on the type of firearm, caliber, and ammunition velocity. Buyers can use these levels to match security needs with the correct panel specification.

UL 752 Protection Levels:

The NIJ (National Institute of Justice) protection levels, while more common in body armor ratings, offer similar guidance for ballistic resistance, focusing on ammunition type and impact energy.

How to Choose the Right Level of Bullet Proofing?

- Threat Environment: Determine likely weapon types based on location risk.

- Application: Higher levels for critical infrastructure, lower for administrative areas.

- Weight & Installation: Higher protection levels mean heavier, thicker panels.

Selecting the correct standard ensures that panels provide effective defense without unnecessary cost or weight.

What are the Different Types of Bulletproof Materials?

Bulletproof materials vary in composition, weight, and performance, allowing buyers to choose a solution that meets both security and design requirements. Three of the most widely used materials are fiberglass, Kevlar, and steel, each offering unique advantages.

Fiberglass Panels:

- Fiberglass Panels are commonly used in bulletproof sheetrock applications.

- Lightweight and non-conductive, ideal for interior walls and counters.

- Absorbs and disperses impact energy through layered construction.

Kevlar Wall Panels:

- Extremely high tensile strength - five times stronger than steel by weight.

- Flexible and can conform to curved or irregular surfaces.

- Resistant to heat and environmental wear.

Steel Panels:

- Highest durability and multi-hit resistance.

- Effective against high-caliber rifles at close range.

- Heavier and more challenging to install; often used in critical infrastructure.

How To Choose the Right Bulletproof Material?

- Security Level: Match the panel to anticipated threats and UL 752 ratings.

- Installation Environment: Consider weight, space, and design requirements.

- Maintenance & Lifespan: Evaluate environmental exposure and wear.

Which Industries Need Bullet-Proof Panels?

Bulletproof panels can be tailored to different industries, ensuring the right level of protection for specific environments. From customer-facing areas to secure back-office spaces, proper selection improves both safety and functionality.

Businesses & Commercial Spaces:

- Bulletproof panels for businesses safeguard teller windows, reception desks, and customer service counters.

- Create discreet security in lobbies and meeting rooms without disrupting design aesthetics.

Financial Institutions:

- Bulletproof walls for banks protect cash handling areas, vault rooms, and secure transaction points.

- Panels integrated into counters and walls deter armed robbery attempts while maintaining customer comfort.

Educational Buildings:

- Install panels in classrooms, entry vestibules, and administrative offices.

- Provide shelter-in-place protection for students and staff during emergencies.

Healthcare Facilities:

- Bulletproof panels for hospitals reinforce reception desks, pharmacy counters, and emergency departments.

- Maintain open, welcoming spaces while reducing risks from potential threats.

Security Doors & Access Points:

- Bulletproof door panels enhance safety in sensitive areas like server rooms, executive offices, or restricted zones.

Bullet-Proof Panel Installation Process – What Buyers Should Know?

Proper installation is essential for bulletproof panels to perform as intended. A well-executed setup ensures both safety and compliance with ballistic protection standards.

Key Steps in Installation:

- Planning & Layout: Identify high-risk zones and ensure adequate structural support.

- Cutting & Preparation: Use diamond-grit saw blades or carbide bits to shape panels without damaging their integrity.

- Mounting: Secure panels directly to wall studs with self-tapping screws or bolts.

- Finishing: Conceal panels behind drywall, millwork, or other finishes for a seamless look.

Safety Considerations:

- Always wear appropriate protective gear to prevent exposure to fiberglass particles.

- Follow manufacturer guidelines to preserve warranty and ballistic certification.

For quality hardware, explore Anchors & Fasteners & Accessories.

DIY vs Professional Bullet-Proof Panel Installation – What’s Safe?

While some steps in DIY bullet-resistant panels installation may seem straightforward, professional services ensure proper safety standards are met.

What all can you do yourself?

- Installing pre-cut panels in small residential spaces.

- Surface finishing with standard construction tools.

What is best left to professionals?

- Cutting and fitting bulletproof fiberglass panels to custom sizes.

- Integrating panels with electrical, HVAC, or security systems.

- Meeting building codes and ensuring ballistic integrity.

Risks of Improper DIY Installation

- Reduced protection due to incorrect fastening.

- Voided manufacturer warranties.

- Potential safety hazards from poor handling of materials.

Power tools, hand tools, sealants, adhesives, & caulking help in making the installation process smoother.

Bullet-Proof Panels: Maintenance, Lifespan, and Cost Breakdown

Proper upkeep ensures bulletproof panels remain effective throughout their service life. Most quality panels can last 5–10 years or longer, depending on the material, installation quality, and environmental conditions.

Maintenance Tips:

- Inspect regularly for signs of impact, wear, or moisture damage.

- Clean with mild soap and water - avoid abrasive or chemical cleaners.

- Maintain proper ventilation to prevent mold or material degradation.

Factors That Affect The Bullet-Proof Panel Lifespan:

- Material Type: Fiberglass and Kevlar often have longer lifespans than steel in corrosive environments.

- Usage: High-traffic or high-risk areas may require more frequent replacement.

- Environment: Humidity, temperature extremes, and UV exposure can affect durability.

Bulletproof Panel Cost:

- Bulletproof panel cost: Level 1–3 panels typically range from $30–$60 per sq. ft.

- Bullet-resistant wall cost: Higher protection levels (4–8) may range from $60–$150+ per sq. ft.

- Additional Costs: Installation labor ($15–$25 per sq. ft.) and finishing materials ($10–$30 per sq. ft.).

Budget Considerations:

- Factor in both installation and finishing when planning projects.

- Higher upfront costs for premium panels can offer longer service life and reduced maintenance.

Bullet-Proof Panels: Our Best-Selling Products Loved By Builders & Architects

Shop Trusted Bullet-Proof Panels from DK Hardware

For businesses, schools, healthcare facilities, or residential projects, DK Hardware offers a range of bullet-resistant panels and complementary security hardware to meet diverse needs. Our solutions are designed to integrate into existing architecture while providing added protection.

Whether you need a few panels for a small installation or bulk quantities for large-scale construction, our team can provide tailored recommendations, accurate quotes, and technical guidance. We work with trusted manufacturers to ensure every product meets strict performance and safety standards.For project consultations or bulk order pricing, contact our sales team at 877-509-8040 or email sales@dkhardware.com. You can also request a quote directly through our website to get started on your security upgrade.