Wrench Size Chart & Guide: SAE vs. Metric, Conversion Tips & How to Choose the Right Wrench?

Picking the right wrench sounds simple until you're standing before a jammed bolt, unsure whether to grab a 10mm or a 3/8". From homeowners assembling furniture to mechanics tuning engines, wrench sizing confusion is incredibly common. The overlap between SAE and metric systems only adds to the frustration.

And it’s not just about fit. Using the wrong wrench size can strip fasteners, damage tools, or slow down your work. That’s why having a reliable wrench size chart and understanding how to use it is essential, whether you're a DIYer or a professional.

In this guide, we’ll walk through wrench sizing systems, show you how to convert between standard and metric sizes, and help you choose the right tool for the job. You’ll also find practical tips and sizing tables that go beyond what most packaging (or hand tool boxes) tell you.

Understanding Wrench Sizing Systems (SAE vs Metric)

If you've ever opened a wrench set and found two sets of numbers, one in fractions and one in millimeters, you’re not alone. Wrenches are commonly made to fit SAE (standard) and metric fasteners, and understanding the difference is key to choosing the right size and avoiding stripped bolts.

What’s the Difference Between SAE and Metric Wrench Sizes?

- SAE (Society of Automotive Engineers) sizes are based on inches and typically shown in fractions like 3/8", 7/16", or 1/2".

- Metric wrench sizes are based on millimeters, such as 8mm, 10mm, 13mm, or 17mm.

SAE sizes are more common in older US-made vehicles and appliances, while metric fasteners dominate in imported goods and newer cars. Today, most homeowners and pros work with both systems regularly.

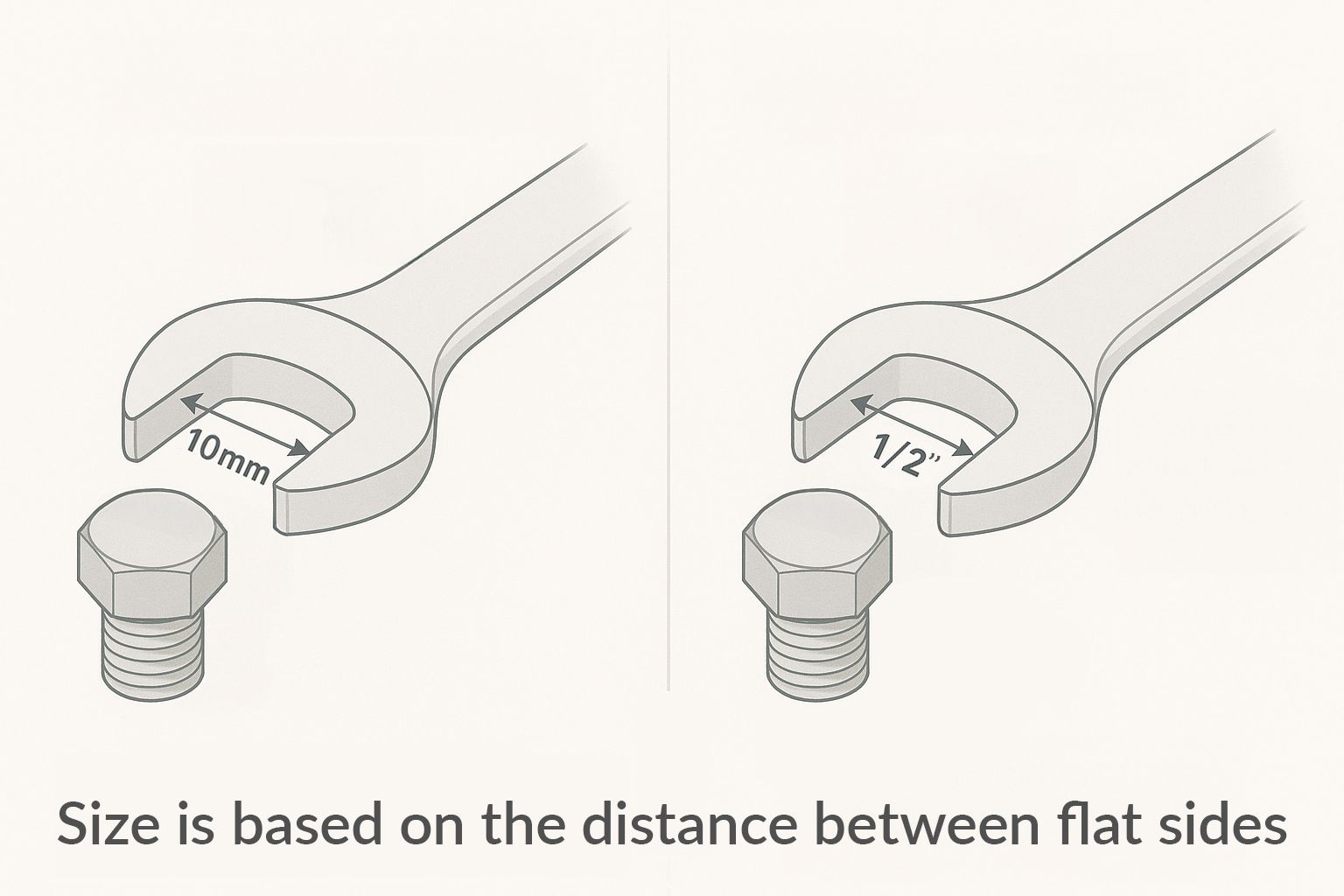

How Wrench Sizes Are Measured?

Both SAE and metric wrenches are measured across the flats of the fastener, meaning the distance between two parallel sides of a hex nut or bolt head. This ensures a snug grip that avoids slippage or damage.

For example:

- A 10mm wrench fits a fastener with a 10 mm-wide head

- A 1/2" wrench fits a fastener that measures half an inch across the flats

This is why size precision matters. A wrench that’s even slightly off can round off the edges of a bolt, especially under high torque.

Why Are Wrenches Often Labeled in Both Units?

Many modern combination wrenches and adjustable wrenches are marked with both SAE and metric scales. That’s because it’s common to encounter both fastener types on the same job, especially when working on newer vehicles, furniture kits, or imported hardware.

Understanding wrench sizing systems helps you move faster on the job, prevents tool damage, and makes your toolset far more versatile.

Wrench Size Chart (SAE to Metric Conversion)

Having both SAE and metric wrenches in your toolbox is practical, but remembering which sizes match can be a pain. That’s where a wrench size conversion chart comes in handy.

Some SAE and metric sizes are close enough to be interchangeable in low-stress applications, while others differ just enough to damage fasteners. The key is knowing which conversions are near-matches and which ones aren’t.

Why Conversions Matter

Let’s say you have a 13mm bolt, but no 13mm wrench in your kit. Can you use a 1/2" wrench instead? Maybe, but tolerances matter. Even a small mismatch can cause rounding or slipping, especially if the bolt is rusted or torqued tightly.

This chart helps you avoid guess game by listing common SAE and metric equivalents.

Larger Wrench Sizes for Heavy-Duty and Industrial Use

While most homeowners won’t go beyond 1-inch wrenches, certain jobs, especially in plumbing, construction, HVAC, and machinery maintenance, call for larger tools. These bigger SAE sizes often align with metric equivalents used in heavy-duty applications.

Use the table below as a quick reference when working with oversized fasteners, large pipes, or structural hardware. It’s especially useful if you’re maintaining commercial equipment or assembling prefab structures.

If you’re working on a mixed project or vehicle, it’s smart to invest in a full wrench set or a well-marked socket wrench kit that includes both SAE and metric options. This ensures you’re not stuck in the middle of a job with a wrench that almost fits.

Most Common Wrench Sizes and Where to Use Them?

You don’t need a 50-piece wrench set to get most jobs done, but you do need the right handful of sizes. Whether you're working on a car, tightening plumbing fixtures, or fixing a bike, certain wrenches tend to get used over and over again.

Here’s a breakdown of the most common wrench sizes and where they show up most often:

Automotive Repairs

Car work demands precision, and fastener sizes vary by make, model, and region of manufacture. If you’re doing automotive maintenance yourself, these are the most frequently used:

Metric:

- 8mm & 10mm: Used on battery terminals, small bolts, and trim components

- 13mm & 15mm: Suspension and engine parts

- 17mm & 19mm: Lug nuts, brake bolts, and heavy-duty areas

SAE (Standard):

- 3/8" & 7/16": Older US vehicles and aftermarket parts

- 1/2": Common for frame bolts, brake calipers, and heavy brackets

Pro Tip: If you're working across imports and American models, keep both metric and SAE wrenches handy.

Plumbing and Home Repairs

For household plumbing, wrenches need to fit pipe fittings, faucet nuts, and sometimes fasteners hidden behind sinks. The most used sizes:

- 7/16", 1/2", and 9/16" – common for faucet connections and under-sink hardware

- 10mm or 13mm – often used in newer fixtures or imported fittings

- Adjustable wrenches also play a big role in tackling odd-sized or corroded parts

Bicycles, Furniture, and Everyday Fixes

A few small sizes pop up again and again around the house:

- 8mm, 9mm, and 10mm – perfect for furniture assembly, wall mounts, and bikes

- 11/32" – a lesser-known SAE size, but often found in lawn equipment or small appliances

These sizes are great candidates for combination wrench sets if you want a basic go-to kit for your garage or kitchen drawer.

Knowing which wrench sizes you’ll reach for most often helps you avoid clutter and invest in the tools that matter for your projects. In the next section, we’ll explore how different types of wrenches (like ratcheting vs open-end) can make the same-size bolt feel like an entirely different job.

Types of Wrenches and When to Use Each

Choosing the right wrench size is only half the battle. The type of wrench you use can make just as much difference, especially in tight spaces, high-torque jobs, or when speed matters.

Here’s a breakdown of the five most common types of wrenches, what they’re best at, and when to reach for each one:

Open-end Wrench

This is a U-shaped opening on one or both ends. Open-end wrenches are ideal for tightening or loosening nuts in spots where you need to slide in from the side

- Pros: Quick access, ideal for wide or awkward angles

- Cons: Less contact with the fastener = more chance of slipping

- Best For: Plumbing fittings, light-duty bolts, tight spaces with no overhead clearance

Box-End Wrench

There’s a closed loop on one or both ends that wraps fully around the fastener. Box-end wrenches offer the most contact and grip, perfect for stubborn or rusted bolts.

- Pros: Less chance of stripping, works well with 6-point and 12-point bolts

- Cons: Requires clearance above the fastener to slip on

- Best For: Automotive bolts, machinery maintenance, high-torque tightening

Combination Wrench

Combination wrenches feature an open-end on one side, box-end on the other. They are a versatile go-to tool that covers most general fastening needs

- Pros: Two tools in one, flip depending on clearance and torque

- Cons: Fixed size means you’ll need a full set to cover your bases

- Best For: DIY tool kits, contractors, and anyone wanting flexibility

Adjustable Wrench

With their movable jaw that adjusts to fit a range of bolt sizes, adjustable wrenches are perfect for quick jobs where you don’t know the fastener size in advance

- Pros: One tool replaces multiple fixed-size wrenches

- Cons: Less precise fit; may slip under heavy pressure

- Best For: Casual home repairs, plumbing work, bike and appliance fixes

Ratcheting Wrench

These come with a ratcheting mechanism at the boxed end that lets you turn fasteners without removing the wrench. They are helpful when you want to speed up repetitive tasks in small spaces.

- Pros: No need to lift and reposition, great for engine bays and under sinks

- Cons: Slightly bulkier than traditional box-end wrenches

- Best For: Automotive work, HVAC, and anywhere speed and access matter

Can You Use Metric and SAE Wrenches Interchangeably?

Sometimes, yes but it actually depends on the job. A few SAE and metric sizes are close enough to be swapped in a pinch. For example:

- 13mm ≈ 1/2"

- 19mm ≈ 3/4"

- 10mm ≈ 3/8"

These pairings might work fine when you're hand-tightening low-stress hardware. But if you're dealing with a rusted bolt, high torque, or delicate components, even the tiniest size difference can round off bolt heads or damage your tools.

If you frequently work on mixed hardware, it's worth investing in a proper wrench set that includes both systems. It saves time and reduces the risk of stripped fasteners—especially if you're using torque-sensitive tools like precision wrenches.

All in all, if it’s a loose fit, don’t force it.

How to Choose the Right Wrench For Your Project?

The best wrench isn’t always the biggest or the most expensive. It’s the one that fits the fastener and the situation.

Here’s how to choose the right wrench:

- Buy a full set if you're just starting out. It’s more cost-effective than buying one wrench at a time, and you’ll always have the right size ready. Look for hand tool sets with both SAE and metric options.

- Use fixed wrenches for high-torque jobs. They offer better grip than adjustable ones and are less likely to slip.

- Go adjustable for quick fixes, odd sizes, or when you’re short on space. Just be sure to snug them tight before applying force.

- Choose ratcheting wrenches when speed matters like engine bays, tight spaces, or repetitive bolts.

And don’t forget to store your tools properly. A cluttered workbench leads to misplaced sizes and damaged tools. Try tool storage organizers that keep everything in its place.

Start Building Your Toolbox with DK Hardware Today

If you've ever reached for the wrong wrench, or worse, forced the wrong one into place, you already know why this guide matters. Understanding wrench sizes, types, and conversions isn’t just for pros. It saves time, prevents damage, and makes every job smoother.

From precise auto repairs to quick household fixes, the right wrench makes all the difference.

Browse our full range of wrenches and hand tools, and keep an eye on this space for more ideas and blogs. Don’t forget to follow us on Instagram, Facebook, & Pinterest for instant industry trends and updates.