Top Drilling Tips & Techniques for Diamond Drills

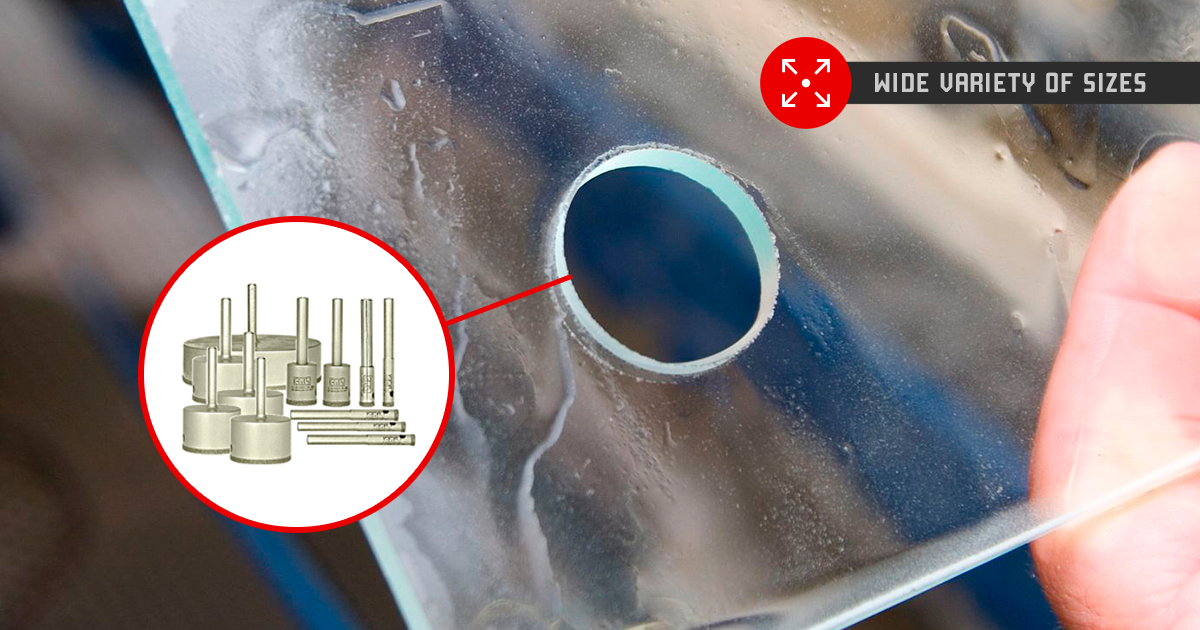

Drilling through hard materials like stone or glass can be a considerable challenge, even if you are an experienced operator. With advancements in technology and manufacturing, a good diamond bit can cut quickly and precisely through everything from concrete and stone to glass panes. Diamond drilling, also known as diamond core drilling, refers to the diamond drill bit used with industrial-grade diamonds set into a metal matrix. So, if you are keen to learn more about it, this blog is for you.

Types of Diamond Drills

Diamond drills come in various types and have different functions. Below are some of the common types of diamond drills you might want to have a look at:

1) Standard Plated Diamond Drills

They have a sturdy construction of premium materials that allow quick hole drilling with clean break-outs. Their impressive diameter shank allows for a sure fit into any drill machine. DK Hardware offers a wide range of Standard plated diamond drills that are sure to suit your preferences. For example:

CRL Standard Plated Diamond Drill - EDD1

CRL Standard Plated Diamond Drill Set - DDK8

2) Metal Bond Diamond Drills

These types of diamond drills are suitable for glass drilling. They use a special diamond and brass bond for maximum performance in glass. DK Hardware offers a wide range of metal bond diamond drills that are sure to suit your preferences. For example:

CRL PD Straight Series Metal Bond Diamond Drill- PD218

CRL PDT Belgian Series Metal Bond Diamond Drill- PDT48MM

3) Short Run Plated Diamond Drills

These diamond drills will make an exceptional choice for drilling work that does not require a high yield of holes. DK Hardware offers a wide range of Short-run plated diamond drills that are sure to suit your preferences. For example:

CRL 1" Short Run Plated Diamond Drill- SRDD1

CRL 5-Piece Short Run Plated Diamond Drill Set- SRK5

4) Miniature Plated Diamond Drills

These types of drills are designed for use in handheld rotary tools. They have a high-construction build and are perfectly suitable for carving, etching, and scribing glass. DK Hardware offers a wide range of Miniature plated diamond drills that are sure to suit your preferences. For example:

CRL .75mm Miniature Plated Diamond Flat-Tip Drill - MD346

Tripple-Ripple .75 mm Plated Diamond Drill - TRD346

Tips to Improve Diamond Drilling

Lubricate Your Diamond Drills Well

Always use water or coolant to cool and lubricate the tip. The lubrication reduces heat build-up, avoids heat fractures in the material, prolonging the drill bit life. Water is the most often used lubricant because it works very well and has no cost. Also, you should avoid using oil-based lubricants as they do not work well with diamond drill bits.

Select the Right Bit for Your Drill

Bit selection is one of the most important aspects of optimizing diamond drilling performance. Knowing what type of ground conditions and rock formations will be encountered goes a long way in selecting the right bit for the job. As with most drilling, ground conditions can vary throughout the drill hole, and often the bit might require to be changed to suit the changing ground. However, knowing when to change a bit, and which bit to put on, is essential for optimal performance.

Maintain Your Diamond Drills

Maintaining your drills includes regular cleaning, lubricating, and servicing. A well-maintained rig optimizes the performance of any drilling program.

DK Hardware features a wide range of diamond drills for your various drilling purposes. Available in different shapes, types, and sizes, they are a must-have for all your drilling needs. Click on any link on this blog to be redirected to some of the best options.

For any specific questions, feel free to reach out to us!

For quotation contact via email: sales@dkhardware.com or

Toll-Free: 877-509-8040